NITE Alert_79

February 6, 2007

Safety alert - Prevention of burning incidents involving microwavable foot warmers

With the recent increase in use of microwavable foot warmers (*1), accidents causing burn injuries have been observed due to excessive heating. NITE implemented product safety tests by purchasing those products available in the market (*2). The results of these tests showed that in some products, the explosion of containers or contents leaks would occur when heated excessively, which may cause consequential burns/scalds.

- (*1)Bags made of resin film or resin cases filled with lagging materials which are designed to be heated in the microwave to retain heat for use as foot warmers, etc.

- (*2)Although microwave instruction manuals discourage heating non-food materials, this test is not concerned with the issue of heating non-food materials in a microwave. This is a reminder for the safe use of foot warmers.

Alert

- (1) Always be sure to follow the instructions for power and heating time. Excessive heating may damage or rupture bags/cases, causing high temperature heated materials to spatter and cause burn injuries.

- (2) Turn off a microwave immediately if the bag inflates or the contents (gel or liquid) leak. Leave enough time for the contents to cool before opening the microwave door.

- (3) Do not reheat while the warmer is warm, or follow reheating instructions if available.

- (4) Do not use a microwave in automatic mode to prevent excessive heating.

- (5) Stop using a foot warmer immediately if it becomes less elastic or if cracks begin to appear as the bag may deteriorate over time.

- (6) Be very careful when removing a foot warmer from the microwave as the bag/case may become very hot (100C) in some areas even when heating as instructed.

1. Background

NITE has received information on accidents involving microwavable foot warmers, such as consumers suffering burns from leaked contents of warmers or from cases exploding when removing them from a microwave.The Ministry of Economy, Trade and Industry (METI) alerted consumers on October 2, 2006, in response to serious burn incidents due to exploded microwavable foot warmers. METI also ordered accident reports from their manufacturers / distributors in compliance with Section 83 of the Consumer Products Safety Law. Since there are many similar products available in the market, NITE implemented product safety tests by purchasing these products.

2. Summary of the test result

2.1 Sample products

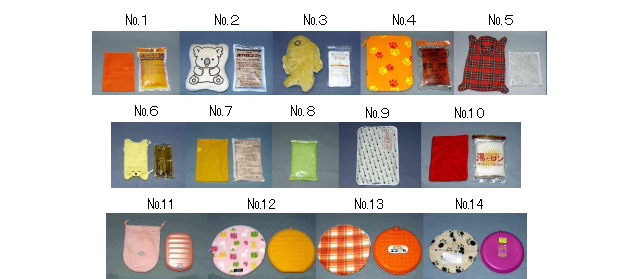

In determining test objects, 14 samples were chosen from the market, of which 9 were gel type, 4 solid (liquefied by heat), and 1 liquid. They were purchased from retailers or by mail-order between November 2 and 13. Modifications made after purchasing are not considered in this test.

2.2 Test method

All samples were tested in the following four patterns which take actual usage patterns into consideration. In addition, a test was conducted to evaluate the probability of damage by dropping.

- (1) Heating as instructed

- (2) Heating excessively against instructions

- Reheating while warm

- Heating at higher output power than instructed in maximum allowed time

- Heating continuously until damage occurs

Drop tests were also implemented after test 1 to find whether the samples would be damaged. In addition, instruction manuals were examined to see if they included safety precautions.

2.3 Test results

- (1) Heating as instructed

Bags/cases of 14 samples did not indicate problems such as inflation, melting, explosion. However, in 2 samples (Sample No.10 and 14), surface temperatures reached 100C. - (2) Heating excessively

- Reheating while they are warm

Bags were inflated in some products (No.5, 13 and 14). Repeating inflation and deflation may cause a consequent deterioration in strength on a long-term basis. Surface temperature on some samples (No. 5, 10, 13 and 14) rose to 100-140C. - Heating at higher output power than instructed

While heating, the resin case of one sample (No. 11) exploded. The force burst open the microwave door, and the liquid filling, at 99 C, splashed out. There was another sample that almost exploded (No.5). - Heating continuously until damaged The test showed differences in effusion conditions of the contents. Resin film bags became damaged relatively quickly - in minutes, and gel filling flowed out. One of the samples (No.3) became damaged in less than 2 minutes. On the other hand, products with resin cases took as long as 15-20 minutes before damage occurred. The test showed that time to damage was generally proportional to the designated heating times given in instructions. Temperatures of the fillings that flowed out were measured at about 100 C for gel or liquid types, and over 200 C for solid types. In some products (No.9 and 11), the force of the explosion burst open the microwave door allowing filling to splash out. Also, there were some samples (No. 10, 12, 13 and 14) whose filling flowed out from the bottom of the microwave door.

- Drop tests

No defects were detected in drop tests with all 14 samples after reheating.

- Reheating while they are warm

- (3) Comparison of descriptions in instruction manuals

Manuals were examined for safe handling instruction content. Only one sample (No.12) covered all of the following instructions in its manual.- Instruction label on power output and time of heating

- Improper heating may pose explosion of the container

- What to do when leakage is seen / Concern about avoiding burns

- To stop heating when the bag is visibly inflated

- Not to open a microwave door right away when the bag is visibly inflated

- How to reheat

- Not to heat in automatic mode

Appendix

1.Samples

Microwavable foot warmers vary in lagging materials, bead, gel, solid (*1), and liquid, etc. For these tests fourteen samples, which use the gel, solid or liquid lagging reported to have caused accidents, were purchased from the market (*2).

- *1:

- Solid but liquefied by heat

- *2:

- Purchased in November 2006 at retail shops or mail order

| No. | Brand name | Name of Manufacturer / Distributor |

Heating instruction (Power / Time) |

Content type | Container type | Country of origin |

|---|---|---|---|---|---|---|

| 1 | Renji de yutapon | Hakugen Co. | 500W: 3min10sec 600W: 2min40sec |

Gel | Double bag | Japan |

| 2 | Hokaron koarano maachi | Lotte Health Products Co. | 500W: 3min30sec (10C) / 3min (15C) 600W: 3min15sec (10C) / 2min45sec (15C) |

Gel | Double bag | |

| 3 | Ohirune pokatan taiyaki | Honyaradoh Co. | 500W: 50sec 600W: 40sec |

Gel | Double bag | China |

| 4 | Yu matto | Terao Corporation | 500W: 3min15sec 600W: 2min45sec |

Gel | Double bag | China |

| 5 | Aroma foot warmer | Natural Wave | Within 3min *3 | Gel | Bag | China |

| 6 | Hiepoka wanwan | Nihon Paff Co. | 500W-600W: 50sec - 1min15sec |

Gel | Bag | |

| 7 | Kaion-kun yutanpo | Okamoto Inc. | 500W: 3min30sec (10C) / 3min (15C) 600W: 3min15sec (10C) / 2min45sec (15C) |

Gel | Double bag | |

| 8 | On aisu | Kenyuu Co. | 500W-600W: 3min *4 | Gel | Bag | |

| 9 | Hot & Cool | Fujisho Co. | 500W: within 4min 600W-1000W: within 2min |

Gel | Double bag *5 | Taiwan |

| 10 | Yutaron | Sanyo Engineering Co. | Within 600W : approx. 4min *6 Within 700(800)W: approx. 3min30sec Within 900(1000)W: approx. 3min |

Solid | Double bag | Japan |

| 11 | Yupon | ENG Hashimoto | 500W: 6min (within 10C) / 5min (10-20C) / 4min (20-30C) 600W: 5min (within 10C) / 4min (10-20C) / 3min (20-30C) 750W: 4min30sec (within 10C) / 4min (10-20C) / 3min (20-30C) *7(instruction on the product) within 6 min in 600W |

Liquid | Soft case | |

| 12 | Renji de chinshite pokka poka | DoggyMan H.A. Co. |

500/600W: 5min 700W: 4min 1000W: 2min50sec |

Solid | Hard case | Japan |

| 13 | Ekopoka | Tokyo Kikaku Hanbai | 500/600W: 6min 700W: 5min 1000W: 2min50sec |

Solid | Hard case | Japan |

| 14 | Renji heat pad | KPS | 600-650W: 8min, 700-750W:7min, *8 800-850W: 6min 900-1000W: 5min, 1100-1200W: 3min, 1300-1400W: 2min30sec |

Solid | Hard case | UK |

- *3:

- Instructions were not printed on the product, but on the package, saying "stop heating if the gel pack starts inflating, even if this occurs within 3 minutes".

- *4:

- Instructions were not printed on the product, but on the carry bag.

- *5:

- The inner bag was made of nylon and the outer bag was fabric with a rubber coating on the inside.

- *6:

- Instructions on the package were different to those on the product. The longer heating times (30 sec) are stated in the table.

- *7:

- Instructions on the cotton bag were different to those on the product and the user manual. Instructions on the product and the manual are stated in the table.

- *8:

- Instructions on the product were different to the manual. Instructions on the product are stated in the table

2. Test items, test methods and results

Taking actual usage conditions into consideration, tests were implemented to confirm if any abnormal states, such as inflation or explosion, would be seen, and to measure surface temperatures at 6 points (*) on the bags, etc, and the temperatures of leaked content when samples were heated as instructed and when they were heated excessively. (*) 6 points were the center and two points one quarter of the way in from the edges on both sides. For test conditions, the temperature of the laboratory was 20![]() 2C and the samples were adjusted to 20±0.5C after being kept in a thermostatic oven for four hours, in preparation for each test. The microwave oven used for the tests had adjustable power levels, 500W, 600W, 700W and 1000W, with a capacity of 30 liters, and was designed to heat from the bottom.

2C and the samples were adjusted to 20±0.5C after being kept in a thermostatic oven for four hours, in preparation for each test. The microwave oven used for the tests had adjustable power levels, 500W, 600W, 700W and 1000W, with a capacity of 30 liters, and was designed to heat from the bottom.

2.1 Test by heating as instructed in manuals

- (1) Method

The samples were heated according to instructions (power and time). When multiple instructions were given, tests were performed for all given power/time instructions. - (2) Results

No test samples showed any abnormalities such as inflation or explosion, etc. However, the surface temperatures of parts of samples No.10 and No.14 rose to 100C as shown below.

| 600W | 700W | 1000W | ||||

|---|---|---|---|---|---|---|

| Sample No. | Highest* | Average | Highest* | Average | Highest* | Average |

| 10 | Heating duration: 4 min | Heating duration: 3 min 30 sec | Heating duration: 3 min | |||

| 100C | 81C | 104C | 82C | 106C | 80C | |

| 14 | Heating duration: 8 min | Heating duration: 7min | Heating duration: 5 min | |||

| 97C | 77C | 100C | 75C | 93C | 66C | |

- * Highest temperature of 6 sample points

2.2Reheat test

- (1) Method

To confirm the safety of the samples when reheated while still warm, the samples were heated under the same conditions as stated above in "2.1 Test by heating as instructed in manuals "and later, when their surface temperatures cooled down to about half the temperature increase caused by heating (*9), they were heated again in accordance with "2.1 Test by heating as instructed in manuals" conditions. Also, a drop test (samples dropped from a height of 30cm onto a wooden board) simulating users dropping foot-warmers onto tables etc., when removing them from a microwave after re-heating, was conducted to see if the samples would be damaged.- *9:

- “Temperature increase” means the difference between sample temperatures before and after heating.

- (2) Results

The table below indicates the samples showing abnormal states. Inflation was seen with the bags or hard cases of samples No.5, 13 and 14, and the surface temperatures reached 100C in samples No.5, 10, 13 and 14. Temperatures for No.10 and No.14 rose as high as 140C. No defects were detected in drop tests with all samples.

| Sample No. | Surface temperature of samples (C) | Description of deformation/breakage | ||||

|---|---|---|---|---|---|---|

| Heating power | 500W | 600W | 700W | 1000W | ||

| 5 | Pre-heat temperature | 38 | 38 | - | - | Expanded about 5cm in whole when heated at 600W |

| Maximum temperature | 75 | 97 | ||||

| Average temperature *1 | 67 | 87 | ||||

| 10 | Pre-heat temperature | - | 44 | 44 | 45 | No deformation/breakage |

| Maximum temperature | 141 | 145 | 149 | |||

| Average temperature *1 | 127 | 134 | 133 | |||

| 13 | Pre-heat temperature | - | 33 | 34 | 31 | Expanded when heated at 600W and 700W at filling inlet. Slightly slanted in whole after heating. |

| Maximum temperature | 98 | 86 | 67 | |||

| Average temperature *1 | 75 | 69 | 49 | |||

| 14 | Pre-heat temperature | - | 45 | 46 | 47 | Expanded gradually, but not on a grand scale. Slightly deformed resin hard case. |

| Maximum temperature | 138 | 136 | 123 | |||

| Average temperature *1 | 134 | 134 | 116 | |||

- Note:

- Heating instructions for No.5 refers to time (less than 3 min) but not to power. Test was not implemented with power of 700W or more, in compliance with the instruction alerting to stop heating when inflation is seen, as the sample started inflating while heating at 600W.

- *1:

- Average temperature of 6 sample points

2.3 Heating with excessive power

- (1) Method

To simulate users using higher power settings by mistake, samples were heated at 700W (higher power setting of single-function microwaves) and 1000W (maximum power of domestic microwaves). The maximum heating times given in instructions were applied to the respective samples. - (2) Results

The table below indicates samples showing abnormal states such as inflation or explosion, etc. Half of sample No.5 inflated when heated at 700W, and at 1000W, this sample expanded up to 10 cm high. Sample No.11 exploded at 1000W after significant inflation. The intensity of the explosion momentarily forced open the microwave door and the liquid filling splashed out. The temperature of the exploded content was 99C. It is presumed that the high strength of the container of No.11, a soft case made of vinyl chloride resin 2.7 mm thick, allowed the inner pressure to reach high levels. Meanwhile, the surface temperature of samples No.10 and No.14 exceeded 100C.

| Sample No. | Instructed heating time | Heating condition (Power / duration) |

Time started inflating | Temperature of surface | Temperature of contents when burst | Description of leaked contents when containers broke/exploded |

|---|---|---|---|---|---|---|

| 5 | Within 3 min | 700W: 3 min | 2 min 30 sec | 88 | N/A | Inflated about half of the sample |

| 1000W:3 min | 1 min 50 sec | 99 | N/A | Kept inflating when stopped heating, and expanded up to 10 cm high | ||

| 11 | *10 600W: 6 min |

700W: 6 min | N/A | 84 | N/A | No abnormality seen |

| 1000W:6 min | 5 min | N/A | 99 | Inflated greatly and exploded at the top. Briefly burst the microwave door open slightly, and leaked content splashed out of the harness. |

- *10:

- Different heating times were given on the product and in the instruction manual (see *6 of Table 1).

Table shows longest heating times indicated on the product

2.4 Continuous heating test

- (1) Method

The samples were heated continuously at power levels indicated in the instructions until they were confirmed broken or ruptured. The time taken for the samples to break or rupture, the temperatures of leaked contents and the internal temperatures were measured. - (2) Results

Resin film bags burst within minutes allowing the gel contents to leak out. Sample No.3 burst the fastest after 1 minute 42 seconds of heating. Gel type contents of samples No.1 through No.8 did not splash out of the microwave or flow out of the microwave through the bottom of the door. Samples No.9 and No.11 inflated and burst. The microwave door was momentarily forced open by the intensity of the burst, and a significant amount of contents splashed out of the microwave. The outer bag for No.9 is a fabric bag with a rubber coated inside, while No.11 has a soft case made of vinyl chloride resin. The bursts are presumed to have been caused by heightened inner pressures made possible by the high strength outer casings. It took as long as 15-22 minutes of heating to damage samples enclosed in hard resin cases (solid type). Although no contents splashed out of the microwave, large amounts of liquefied hot contents flowed out through the gaps between the main body and door of the microwave. In general, the time required to break a container is proportional to the instructed heating time. In addition, temperatures of contents rose to approximately 100C with gel and liquid types, and liquefied solid contents reached 200C. No.14 hit the highest temperature of 250C.

| No | Heating instruction | Time required to break/explode sample Content temperature |

Description of leaked contents when containers broke/exploded | |||

|---|---|---|---|---|---|---|

| 500W | 600W | 700W | 1000W | |||

| 9 | 500W: 4min 1000W: 2min |

10min 7sec |

N/A | N/A | 5min 33sec |

Continued inflation after the inner bag burst. Explosion of outer bag opened the microwave door briefly, and significant amounts of contents splashed out up to 2.2 meters around. |

| 101C | 101C | |||||

| 10 | 600W: 4min 700W: 3min 30 sec 1000W: 3min |

N/A | 10min 30sec | 9min 14sec | 7min 4sec |

Inflated then broke at the seal. Substantial amounts of contents leaked, and flowed out of microwave through the gap between main body and door. |

| 197C | 217C | 202C | ||||

| 11 | 500W: 5min 600W: 4min 700W: 4min |

9min 23sec | 8min 8sec | 6min 41sec | N/A | Inflated then burst. Intensity slightly opened the microwave door momentarily, and significant amounts of contents splashed out up to 1 meter around. |

| 88C | 88C | 96C | ||||

| 12 | 600W: 5min 700W: 4min 1000W: 2min 50sec |

N/A | 20min 50sec | 16min 31sec | 15min | The container inflated and deformed, then broke at the softened part. Hot liquefied content flowed out from the rupture, and consequently leaked out of microwave through the gap between main body and door. |

| 221C | 208C | 228C | ||||

| 13 | 600W: 5min 700W: 4min 1000W: 2min 50sec |

N/A | 17min 12sec | 14min 30sec | 14min 40sec |

The container inflated and deformed, then broke at the softened part. Hot liquefied content flowed out from the rupture, and consequently leaked out of microwave through the gap between main body and door. |

| 172C | 186C | 194C | ||||

| 14 | 600W: 8min 700W: 7min 1000W: 6min |

N/A | 21min 58sec | 19min 30sec | 16min 50sec |

The container inflated and deformed, then broke at the softened part. Hot liquefied content flowed out from the rupture, and consequently leaked out of microwave through the gap between main body and door. |

| 218C | 235C | 254C | ||||

2.5 Compositional analysis of contents

- (1) Method

The main components of the contents were identified by infrared spectroscopy. - (2) Results

Among samples with gel type contents, samples No.1,2,4,5 and 8 had "polyvinyl alcohol and water" as their main component, while "carboxymethylcellulose sodium and water" was the main component of samples No.3,6,7 and 9. The content of the liquid type sample (No.11) was composed of water, while the contents of No.10,12,13 and 14 (solid type) consisted of "polyethylene glycol".

2.6 Investigation of instructions

- (1) Objectives

To confirm whether the instructions provided the necessary information for safe usage. - (2) Results

The table below indicates the results. Only No.12 met all the requirements. No.7 and 11 showed all instructions other than the instruction to "not to open a microwave door immediately when inflation is observed".

| No. | That misuse (heating power / time) may cause breakage or explosion of container | Warnings for handling and burn hazard when the contents leak | Warnings when inflation is observed | Not to open a microwave door immediately when inflation is observed | Reheating instructions | Not to heat in automatic mode | Instruction of heating time displayed on the product |

|---|---|---|---|---|---|---|---|

| 1 | |||||||

| 2 | |||||||

| 3 | |||||||

| 4 | |||||||

| 5 | |||||||

| 6 | |||||||

| 7 | |||||||

| 8 | |||||||

| 9 | |||||||

| 10 | |||||||

| 11 | |||||||

| 12 | N/A | N/A | |||||

| 13 | N/A | N/A | |||||

| 14 | N/A | N/A |

- * Handling instruction only (no warning for burn hazard)

Fore more information;

National Institute of Technology and Evaluation (NITE)

Product Safety Technology Center, Product Safety Investigation Division

Contact us

- Consumer Product Safety Public Relations Division Product Safety Technology Center National Institute of Technology and Evaluation

-

Phone number:+81-6-6612-2066

Fax number:+81-6-6612-1617

Address:1-22-16 Nankokita, Suminoe-ku, Osaka-shi, Osaka 5590034, Japan MAP